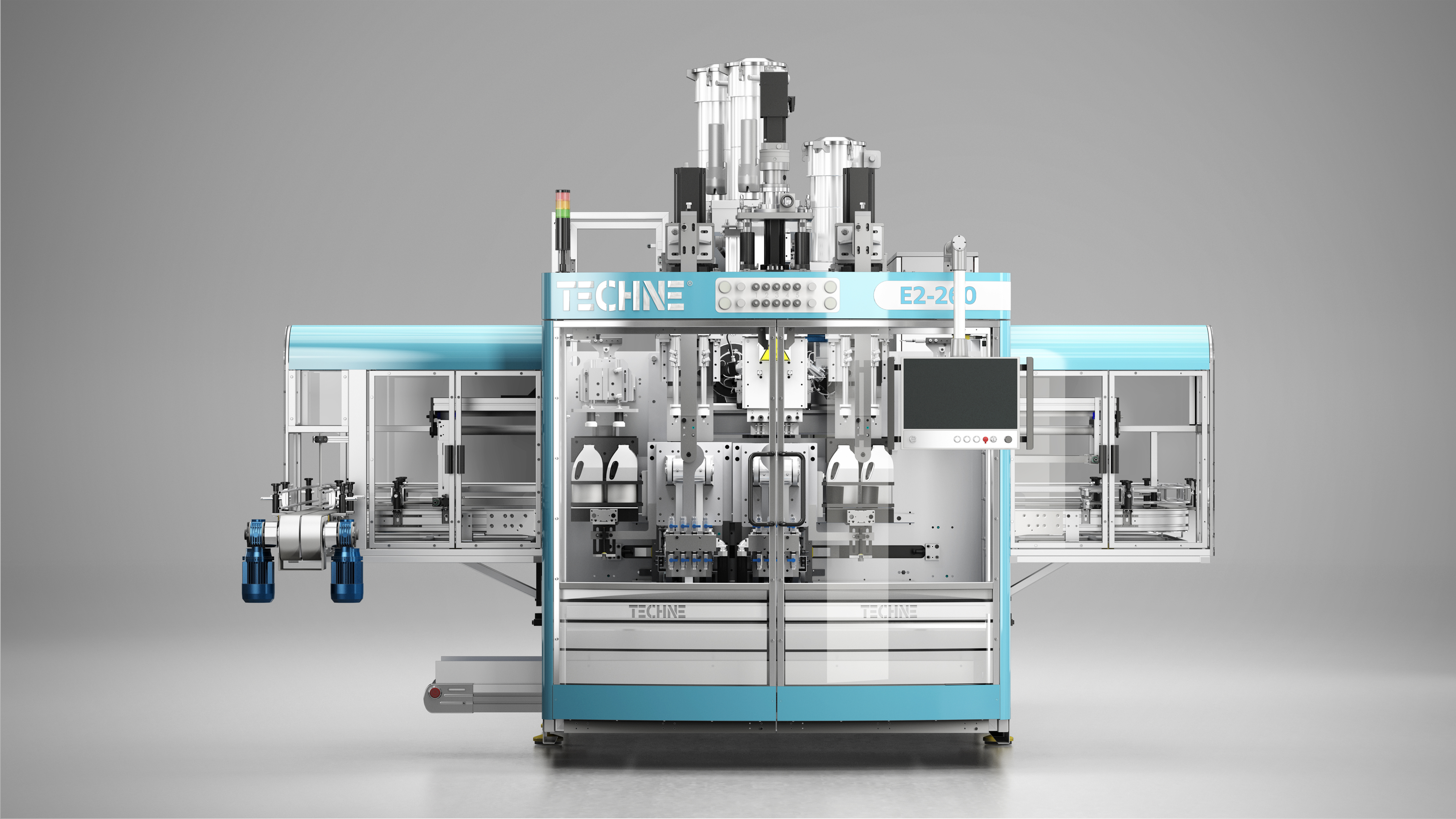

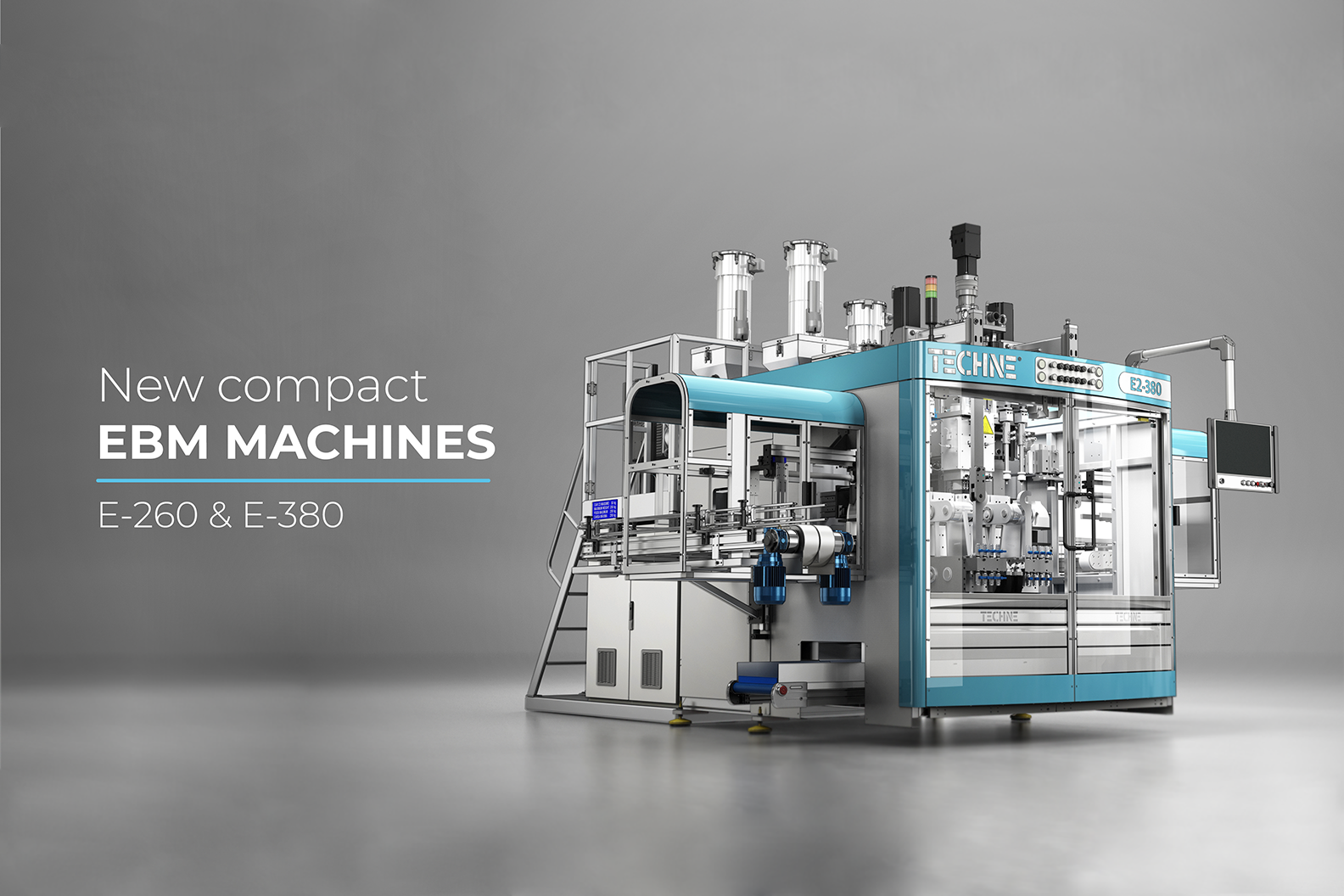

A 100% electric experience with the new 2022 compact EBM machine.

Techne has expanded its offer with a new compact line of Extrusion Blow Molding machine dedicated to reduced productions.

New project born in 2021 aiming to guarantee the same industrial safety and careful choice of high quality Made in Italy components while following a totally innovative and flexible concept.

Despite Techne been focused for many years in high production EBM lines, we are now ready to transfer of more than 35 years of know-how into more flexible production growth requirements.

New compact blow molding machines, designed for reduced bottle production, maintain the same very high quality standard that allows them to be used for over 20 years.

Time to take a step forward.

Do you have an outdated blow molding machine that is difficult to use?

Do you want to increase productivity but don't have much space in the plant?

Do you want to avoid excessive and unnecessary investments?

Modern and digital.

Ease of use of the machine for the operator.

Production efficiency combined with space optimization.

Flexibility and adaptability of molds and tooling.

Flexible & compact,

space is more than a concept.

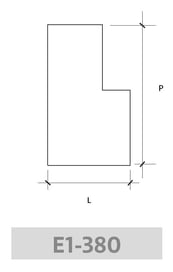

The E-260 and the E-380 can be configured with both Monolayer and COEX (up to COEX 3) extrusion heads and bottle sizes range from 60 ml to about 2L.

The two new models are part of the E-LINE range that offers 3 key benefits: low consumption, low maintenance and high user friendliness.

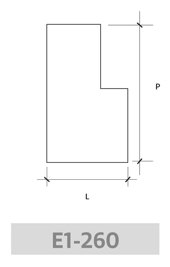

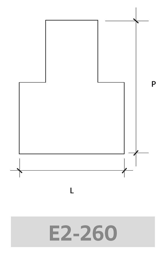

The E-260 and E-380 blow molding machines are available in single and double shuttle configurations:

The main advantages of this new extrusion blow molding:

- Use of a B&R-certified safety system that allows operations of fine tuning on the blow pins or on deflashing also with opened access doors.

- New PLC combined with an intuitive and user-friendly graphic interface for the operator.

- Carriage stroke has several configuration options: the E-260 model can be configured with 260, 280 or 300 mm stroke, whilst the E-380 model with 360, 380 or 400 mm.

- Vertical adjustment system of motorized blow pins: there is no need to stop the machine to vertically regulate the blow pins but simply vary the parameters on the user interface screen.

- Extremely flexible machine type, ideal to the production of different bottle sizes thanks to its tooling adaptability and interchangeability;

- Possibility of installing optional equipment directly inside the machine that are usually placed outside. This saves space in the plant and simplifies the process of forming the finished product.

To discover more, download the datasheet of the new compact Extrusion Blow Molding machines.

Leave a comment